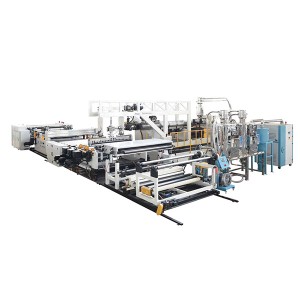

Otlolla Filimi Extrusion Line

Tlhaloso ea Sehlahisoa

Thepa e entsoe ka extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder le tsamaiso ea ho laola. Ho ipapisitse le bokhoni ba rona bo tsoetseng pele ba ho rala le ho sebetsa, likarolo tsa lisebelisoa tsa rona ke:

● Special etselitsoe lognitudinal strech rolara.

● Tsamaiso ea ho khanna le ho laola li tsoa ho brand e tsebahalang lefatšeng ka bophara.

● Tsamaiso ea ho laola e tsoa ho precision PLC program.

● Ho nepahala ho phahameng, lebelo le phahameng, le boemo bo tsitsitseng ba ho sebetsa.

Re khona ho rala lisebelisoa ho latela kopo ea moreki ka lisebelisoa tse otlollang tse nepahetseng: 1-10 streching ratio, bophara ba bophara e tla ba 500-3000mm, bophara ba botenya bo tla ba 0.05-0.3mm.

Casting filimi ke mofuta oa filimi e hlahisoang ke melt casting quenching. Ho na le mekhoa e 'meli: ho lahlela ka lera le le leng le ho lahla ka mefuta e mengata ea coextrusion. Ha e bapisoa le ho foka ha filimi, e tšoauoa ka lebelo la tlhahiso e potlakileng, tlhahiso e phahameng, le pepeneneng e ntle haholo, bokhabane le botenya ba filimi.

Filimi ea ho lahla theipi e na le ts'ebetso e ntle ea ho koala mocheso le pepeneneng e ntle haholo. Ke e 'ngoe ea li-substrates tse ka sehloohong tsa ho paka. E sebelisetsoa ho hlahisa filimi ea ho pheha e nang le mocheso o phahameng le filimi ea vacuum aluminizing. Mmaraka o ts'episa haholo. Ho feta moo, ka nts'etsopele ea lisebelisoa tsa tlhahiso ea lifilimi tsa malapeng, li-index tse ling tsa tekheniki li fihlile boemong bo phahameng ba machaba.

1). Mohala oa tlhahiso ea lifilimi oa malapeng o ka aroloa ka 2500mm, 3000mm, 3500mm le 5000mm ho ea ka bophara ba filimi, 'me o ka aroloa ka likarolo tse tharo, lihlopha tse hlano le lihlopha tse supileng ho ea ka tlhophiso ea extruder.

2).Mohala oa tlhahiso ea lifilimi haholo-holo o entsoe ka karolo ea extrusion, karolo ea ho lahla, karolo ea corona, karolo e matsoelintsoeke le karolo ea taolo ea motlakase. Karolo ea hlobo le karolo ea extrusion e ka kopanngoa ka bolokolohi ho ea ka litlhoko tsa bareki, e le ho finyella litlhoko tse fapaneng tsa bareki (mmaraka) ka tekanyo e kholo ka ho fetisisa.

3). Ntle le moo, moralo oa lisebelisoa tsa lapeng o latela boemo bo tsoetseng pele ba machabeng, joalo ka:

A. Moralo o ikhethang oa sesebelisoa sa extrusion o ka fetola ka bolokolohi khatello ea extruder.

B. Moralo o ikhethileng oa screw runner o ka sebelisoa ho lisebelisoa tse fapaneng ho hlokomela merero e mengata ea mochini o le mong.

C. Moralo oa mocha oa phallo oa rolara o na le phello e ntle ea ho pholile, boleng ba sehlahisoa bo tsitsitseng le tlhahiso e phahameng.

D. Lebelo la mohala oa mohala oa tlhahiso ea lifilimi oa malapeng o fihlile boemong ba 160m / min-350m / min.

4). Ha ho bapisoa le lisebelisoa tse tsoang linaheng tse ling, mohala oa tlhahiso ea lifilimi oa malapeng o boetse o na le litšobotsi tsa lebelo le phahameng, ts'ebetso e tsitsitseng, ts'ireletso ea tikoloho le ho boloka matla.