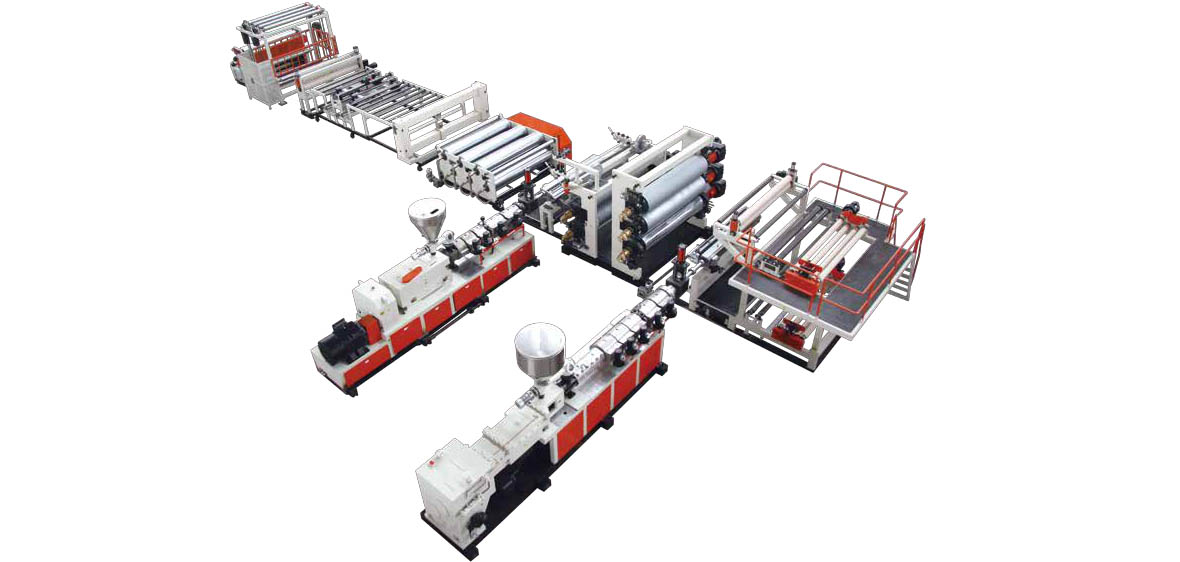

PVC Metsi Sheet Extrusion Line

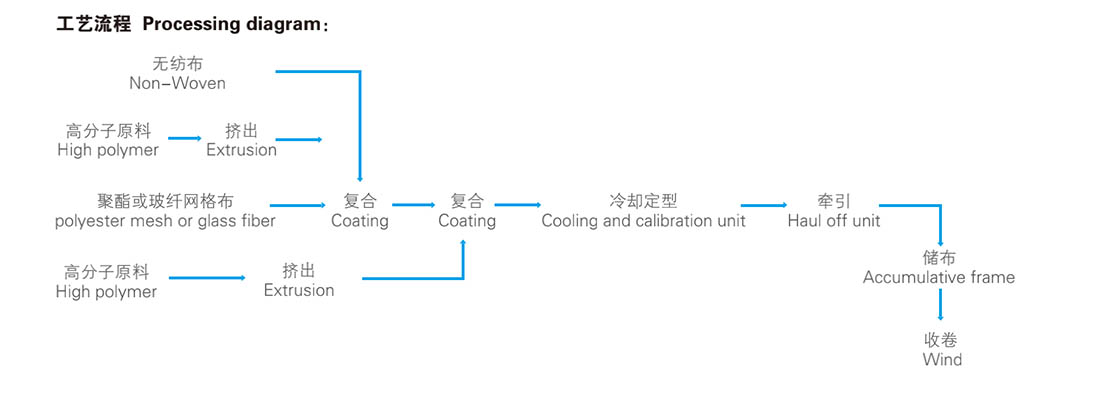

E sebelisoa bakeng sa mefuta e fapaneng ea thepa ea polasetiki, joalo ka PVC, TPO, joalo-joalo Ho khona ho hlahisa maqephe a ka tlase:

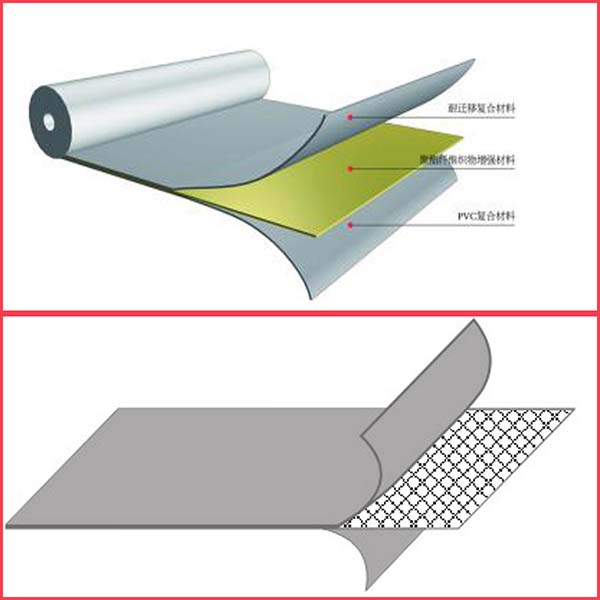

Letlapa la polasetiki (mohlala: H): ntle le ho roala ka thepa e matlafalitsoeng ka hare kapa thepa e ka ntle.

Roll sheet e nang le fiber e ka ntle (Mohlala: L): ho roala ka fiber kapa lesela le sa lohiloeng.

Letlapa le matlafalitsoeng ka hare (Mohlala: P): Liaparo tsa ka hare tse nang le mesh ea polyester.

Letlapa le matlafalitsoeng ka hare (Mohlala: G): Liaparo tsa ka hare tse nang le fiber ea khalase.

Litšobotsi tsa thepa ea PVC e sa keneleng metsi e kopantsoeng (lakane).

1. Lintho tse kopantsoeng tse sa keneleng metsi tsa PVC li na le matla a phahameng a tsitsipano, bolelele bo botle le sekhahla se senyenyane sa phetoho ea boholo ba mocheso.

2. E na le weldability e ntle, 'me lenonyeletso le kopantsoe le tšepe ea motheo ka mor'a ho chesa moea o chesang.

3. E na le diffusivity e ntle ea mouoane oa metsi, condensate e bonolo ho lokolloa, 'me mongobo le mongobo o setseng ho setsi ho bonolo ho lokolloa.

4. Ho hanyetsa botsofali, ho hanyetsa mahlaseli a ultraviolet, k'hemik'hale ea ho senya lik'hemik'hale le ho hanyetsa ho kenella ha metso.

5. E na le maemo a bonolo ka mocheso o tlase (- 20 ℃).

6. Bophelo bo bolelele ba tšebeletso (marulelo a lilemo tse 25, ka tlas'a lefatše ho feta lilemo tse 50) 'me ha ho na tšilafalo ea tikoloho.

7. Bokaholimo ba 'mala bo bonahatsa mahlaseli a ultraviolet,' me bokaholimo ba thepa e sa keneleng metsi ea PVC e monya mocheso o fokolang le mocheso o tlase.

8. Ho tenyetseha le ho atolosoa ho hoholo, matla a phahameng a tsitsipano, botsitso bo botle ba sebopeho, matla a phahameng a mochini, ho hanyetsa khoholeho, ho kenella ha metso, ho hanyetsa boemo ba leholimo, ho lekana ha UV le ho hanyetsa sefako.

Litlhaloso tsa mantlha tsa tekheniki

|

Mohlala |

SJP130/36-SJZ92/188-3400 |

JWP130/26+JWP130/26-2400 |

|

Sebopeho sa sehlahisoa |

TPO+(Nete)+TPO |

PVC+(Nete)+ PVC |

|

Bophara ba lihlahisoa |

3200 limilimithara |

2200 limilimithara |

|

Lihlahisoa tsa botenya |

0.8-3 limilimithara |

0.5-3 limilimithara |

|

Mohlala oa Extruder |

SJP130/36-SJZ92/188 |

JWP130/26+JWP130/26 |

|

Bokhoni |

1200kg/h |

1500kg/h |