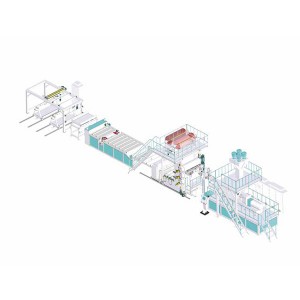

HDPE Thermoforming Plate Extrusion line

Jwell e fana ka sistimi e tsoetseng pele ea extrusion, e loketse ho hlahisa thepa ea HMW-HDPE e nang le MFI e tlase le matla a phahameng ka har'a poleiti, lipoleiti li sebelisoa haholo ho hlahisa boto ea likoloi, lebokose la li-pick-up, sekoaelo sa teraka, anti-pula. sekoahelo joalo-joalo Botenya ba poleiti bo ka fokotsa ho feta 30% ha bo e-na le matla a ts'ebetso e tšoanang, bo fokotsa litšenyehelo tsa tlhahiso bakeng sa bahlahisi. Plate botenya 2-12mm, bophara 2000-3000mm.

Litlhaloso tsa mantlha tsa tekheniki

|

Mohlala |

Bophara ba lihlahisoa(mm) |

Botenya ba lihlahisoa(mm) |

Bokhoni(kg/h) |

|

JW130+JW70 |

2200 |

1.5-12 |

600-700 |

|

JW150+JW90 |

2600 |

1.5-12 |

800-900 |

Tlhokomeliso: Litlhaloso li ka fetoha ntle le tsebiso esale pele.

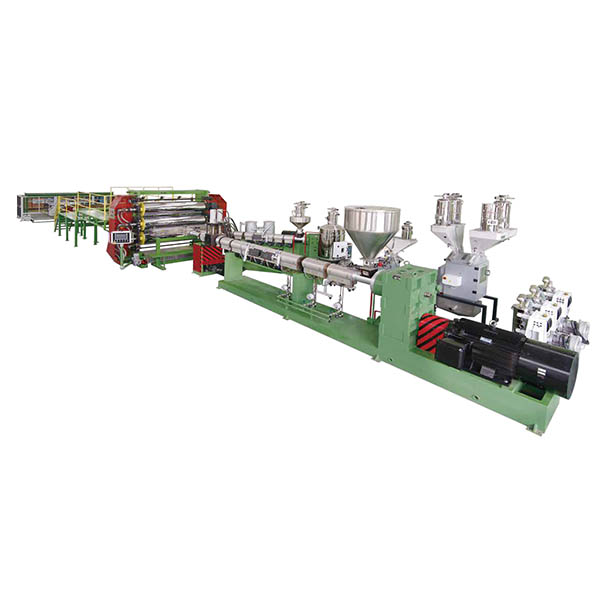

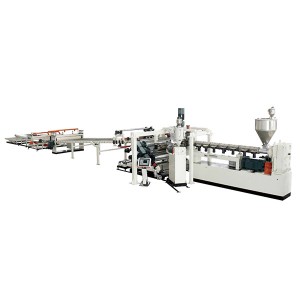

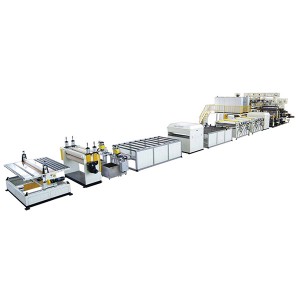

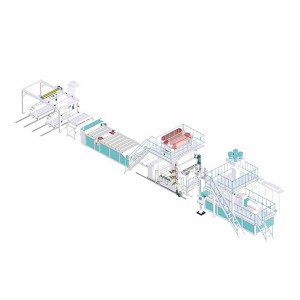

Pontšo ea setšoantšo sa sehlahisoa

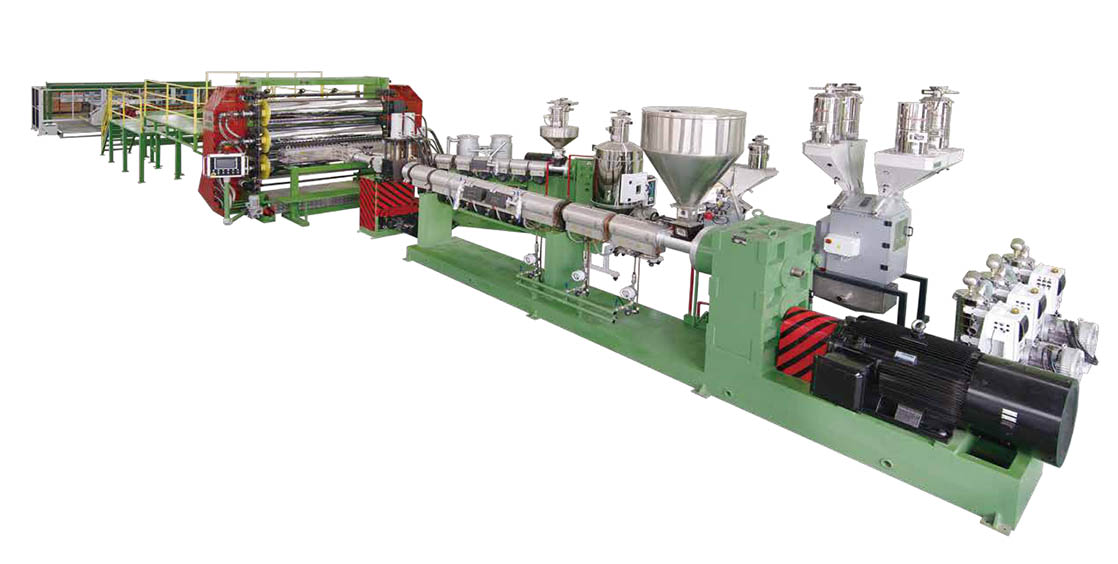

Sistimi ea phetiso

Mosebetsi oa tsamaiso ea koloi ke ho khanna screw le ho fana ka torque le lebelo le hlokoang ke screw ts'ebetsong ea extrusion. Hangata e na le enjene, e fokotsang le e behang.

Sesebelisoa sa ho futhumatsa le ho futhumatsa

Ho futhumatsa le ho pholisa ke maemo a hlokahalang bakeng sa ts'ebetso ea extrusion ea polasetiki.

1. Hangata extruder e sebelisa mocheso oa motlakase, o arotsoeng ka mocheso oa ho hanyetsa le ho futhumala ha induction. Letlapa la ho futhumatsa le kenngoa 'meleng, molala le hlooho. Sesebelisoa sa ho futhumatsa se futhumatsa polasetiki ka har'a silinda ka ntle ho eketsa mocheso ho fihlela mocheso o hlokahalang bakeng sa ts'ebetso ea ts'ebetso.

2. Sesebelisoa sa ho pholile sa extruder se behiloe ho etsa bonnete ba hore polasetiki e boemong ba mocheso o hlokahalang ka mokhoa ona. Haholo-holo, ke ho qhelela ka thoko mocheso o feteletseng o hlahisoang ke ho hohlana ha sekiri ho bakoang ke ho potoloha ha screw, e le ho qoba hore mocheso o be holimo haholo ho etsa hore polasetiki e bole, e tlabohe kapa sebopeho se thata. Pholiso ea moqomo e arotsoe ka mefuta e 'meli: pholileng ea metsi le moea o pholileng. Ka kakaretso, li-extruder tse nyane le tse mahareng li loketse ho pholisa moea, 'me tse kholo haholo li pholile ka metsi kapa li kopantsoe le mefuta e' meli ea ho pholisa.