Mochini oa ho boloka matla oa HDPE o Tiileng oa Lebota Pipe e Phahameng ka ho Fetisisa

Ha ho bapisoa le liphaephe tsa setso, tsamaiso ea lipeipi tsa HDPE e na le melemo e latelang

(1) khokahanyo e ka tšeptjoang: Sistimi ea lipeipi tsa polyethylene li hokahantsoe ke fusion ea electrothermal, 'me matla a lenonyeletso a phahame ho feta a' mele oa phala.

(2) ho hanyetsa phello e ntle ea mocheso o tlase: mocheso o tlase oa mocheso oa polyethylene o tlase haholo, 'me o ka sebelisoa ka mokhoa o sireletsehileng mocheso oa - 60-60 ℃. Nakong ea kaho nakong ea mariha, ho kenngoa ha pipe ho ke ke ha etsahala ka lebaka la ho hanyetsa tšusumetso e ntle ea thepa.

(3) khanyetso e ntle ea khatello ea maikutlo: HDPE e na le kutlo e tlase ea notch, matla a phahameng a ho kuta le khanyetso e ntle ea ho hlaba, 'me khanyetso ea eona ea khatello ea tikoloho le eona e ikhethile haholo.

4 Polyethylene ke insulator ea motlakase, kahoo e ke ke ea bola, mafome kapa electrochemical corrosion; Ho feta moo, ha e khothalletse kholo ea algae, libaktheria kapa li-fungus.

(5) ho hanyetsa botsofali le bophelo bo bolelele ba tšebeletso: liphaephe tsa polyethylene tse nang le 2-2.5% ea carbon black e arolelitsoeng ka mokhoa o tšoanang li ka bolokoa ka ntle kapa tsa sebelisoa ka lilemo tse 50 ntle le ho senngoa ke mahlaseli a kotsi.

(6) ho hanyetsa ho apara hantle: teko ea ho bapisa ho hanyetsa pakeng tsa phala ea HDPE le phala ea tšepe e bontša hore ho hanyetsa ha phala ea HDPE ke makhetlo a 4 a phala ea tšepe. Sebakeng sa lipalangoang tsa seretse, ha ho bapisoa le pipe ea tšepe, pipe ea HDPE e na le khanyetso e ntle ea ho apara, e bolelang hore pipe ea HDPE e na le bophelo bo bolelele ba tšebeletso le moruo o molemo.

(7) ho feto-fetoha ha maemo: ho tenyetseha ha phaephe ea HDPE ho etsa hore ho be bonolo ho koba. Boenjiniere, litšitiso li ka fetisoa ka ho fetola tsela ea lipeipi. Maemong a mangata, ho feto-fetoha ha liphaephe ho ka fokotsa tšebeliso ea lisebelisoa tsa liphaephe le ho fokotsa litšenyehelo tsa ho kenya.

(8) khanyetso ea phallo e nyane: Pipe ea HDPE e na le bokaholimo bo boreleli bo kahare, 'me coefficient ea eona ea Manning ke 0.009. Ts'ebetso e boreleli le litšoaneleho tse sa khomarelang li netefatsa hore phaephe ea HDPE e na le bokhoni ba lipalangoang bo phahameng ho feta lipeipi tsa setso, hape e fokotsa tahlehelo ea khatello le tšebeliso ea matla a phepelo ea metsi.

(9) ts'ebetso e bonolo: Pipe ea HDPE e bobebe ho feta phala ea konkreite, phala e entsoeng ka masenke le phala ea tšepe. Ho bonolo ho sebetsana le ho kenya, 'me litlhoko tse tlaase tsa mosebetsi le lisebelisoa li bolela hore litšenyehelo tsa ho kenya morero li fokotsehile haholo.

(10) mefuta e fapaneng ea mekhoa e mecha ea kaho: Lipeipi tsa HDPE li na le mefuta e fapaneng ea theknoloji ea kaho. Ntle le mokhoa oa khale oa ho epolla, o ka hahuoa ka mefuta e fapaneng ea mahlale a macha a sa epollang, joalo ka ho phunya liphaephe, ho phunya ka tsela, ho phunya lipeipi, joalo-joalo. lumelloa.

Ts'ebetso le melemo ea lisebelisoa tsa rona

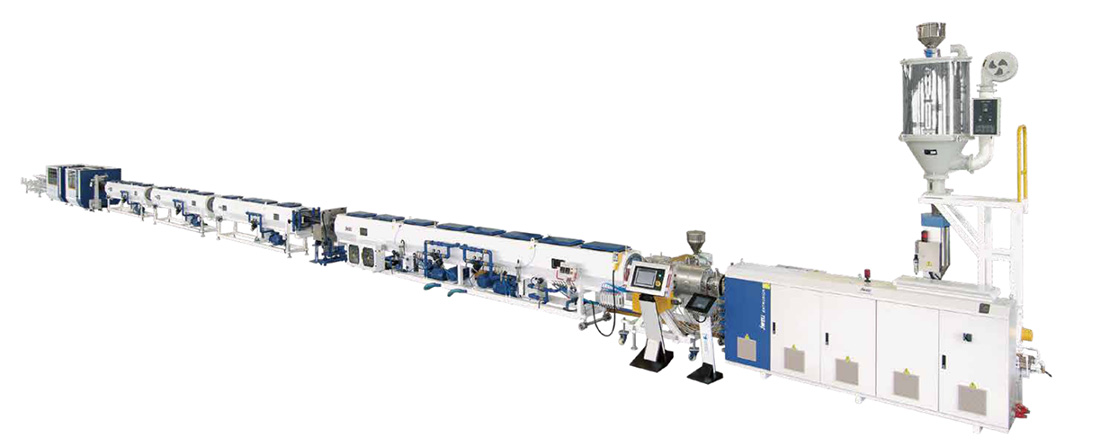

Patlisiso ea morao-rao ea k'hamphani ea rona le nts'etsopele ea mohala oa tlhahiso ea lebelo le phahameng o bolokang matla, o loketseng ho extrusion ea phala ea polyolefin ea lebelo le holimo. 35% ea ho boloka matla le ho eketseha ha 1x ka katleho ea tlhahiso.Sebopeho se entsoeng ka ho khetheha sa 38-40 L / D screw le barrel ea slot ea ho fepa e etsa hore ho qhibiliha ho qhibilihe le liphello tsa polasetiki li ntlafatse haholo. Li-gearbox tsa torque e phahameng, tse matla a phahameng li netefatsa ts'ebetso e tsitsitseng ea lisebelisoa.

Li-mold tsa Extrusion le matsoho a boholo li nka sebopeho se tsoetseng pele ka ho fetisisa. Tanka ea vacuum ea taolo ea maqhubu a PLC, terekere e tsamaeang ka litebelisoa tse ngata e tsamaisoang ke servo, le sekhechana se sehang se nang le lebelo le holimo li na le sistimi ea taolo ea boima ba mithara. Boima ba phala ea extrusion bo nepahetse haholoanyane.

Litlhaloso tsa mantlha tsa tekheniki

|

Mohlala |

Pipe diamete |

Extruder |

Bokhoni |

Matla a Maholo |

|

JWPEG-H75 |

Φ16-75 limilimithara |

JWS-H60/40 |

350kg/h |

90kw |

|

JWPEG-H125 |

Φ20-125 limilimithara |

JWS-H60/40 |

450kg/h |

110kw |

|

JWPEG-H160 |

Φ50-160mm |

JWS-H75/38 |

550kg/h |

132kw |

|

JWPEG-H315 |

Φ75-315 limilimithara |

JWS-H75/38 |

650kg/h |

160kw |

|

JWPEG-H500 |

Φ160-500mm |

JWS-H90/38 |

900kg/h |

250kw |

|

JWPEG-H630 |

Φ315-630 limilimithara |

JWS-H90/38 |

1050kg/h |

280kw |

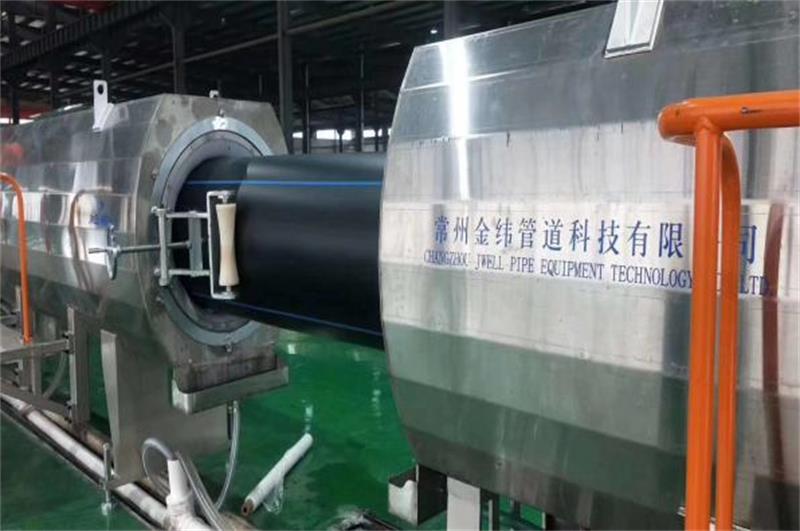

Pontšo ea setšoantšo sa sehlahisoa